(Published in the Winter 2020 Edition of IMPACT magazine, a publication of the Virginia Western Community College Educational Foundation.)

By Karenna Glover

Returning students in the STEM program at Virginia Western Community College didn’t recognize their learning space when classes began in Fall 2019. The new contemporary classrooms filled with TV monitors, modular furniture and the most modern equipment were a far cry from the classrooms in 50-year-old Anderson Hall, with its traditional wooden desks, chalkboards and projectors.

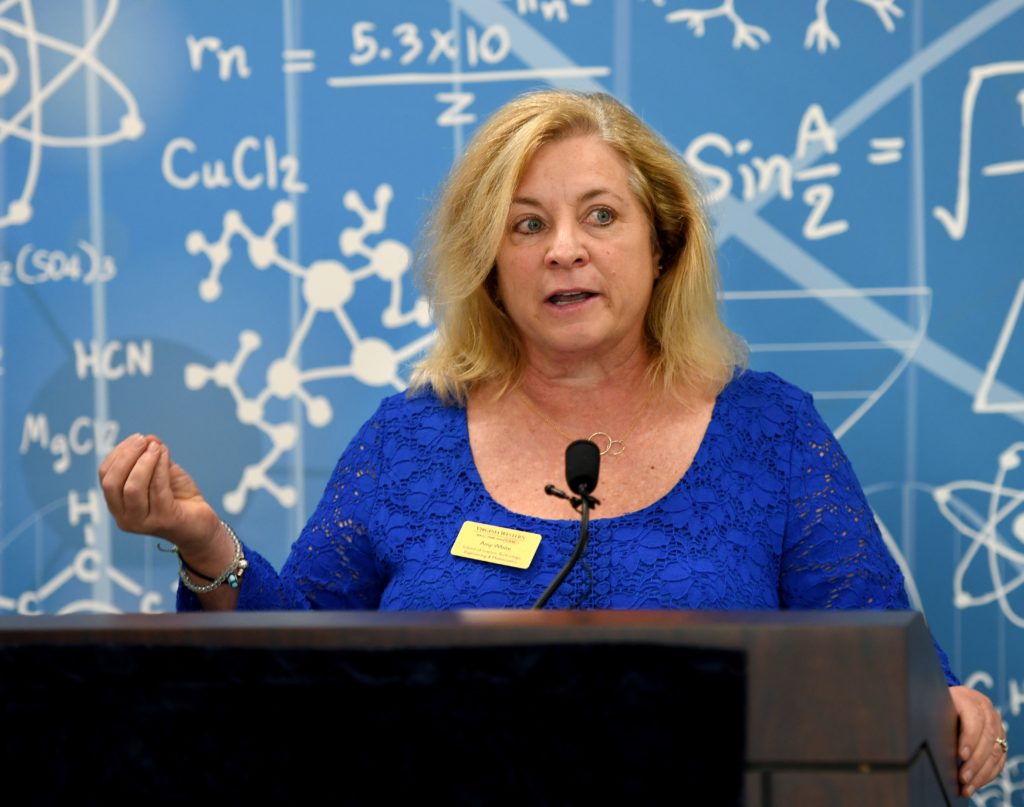

The new 72,000-square-foot space houses many of Virginia Western’s programs for Science, Technology, Engineering and Mathematics (STEM), and is now the single largest building on the Colonial Avenue campus. The building and its state-of-the-art equipment represent what STEM Dean Amy White has envisioned to provide students the most ideal learning environment and prepare them for long-lasting careers.

“To me, the building is about preparing students for jobs that don’t yet exist,” White said. “The space allows them to focus on critical thinking, problem-solving skills and communications skills. (But) it’s not about the equipment. It’s not about the buttons on the machine. It’s about why the buttons are on the machine, and how the students can solve problems using the latest and greatest equipment.”

Building construction by Branch & Associates began in 2016, but design of the space began years earlier, and input from faculty and students is woven throughout the four-story building.

“Who knows better what students need than the faculty? The space was designed with an understanding of what works best for students and how they learn and engage,” White said.

Alif Hill, a second-year mechatronics major, was excited to see the building open and was deeply invested in the space, as he offered suggestions on the design and selection of some equipment in the new Fab Lab, including new 3-D printers. “The new building feels personal. I feel like a kid on Christmas, with all new toys,” Hill said. “I’m so excited to use the new equipment in the space.”

Tucked in the corners of each floor is space dedicated for student study, both independent and collaborative, as well as an office for walk-in tutoring where students can get peer-to-peer tutoring.

Classrooms in the $37 million facility were designed to be open and flexible, allowing students and faculty to easily move from lecture-style learning to group-work. White boards cover the walls and 80-inch TV monitors mounted in corners replace traditional chalkboards.

“It may sound simple and small, but I’m excited with how the seats are arranged in the new building,” said Assistant Professor of Mechatronics David Berry, noting the more open space with movable tables and chairs. “I hope it will allow me to reach my students in a better way. The new space offers us a chance to all work together, where everyone can touch things and collaborate.”

This concept of collaboration offered by the new space extends beyond the faculty and students to the community. Virginia Western leaders envision other students at other colleges, community organizations and companies across the region using both the space and new equipment. The new biotechnology suite may draw use from students and faculty from the Fralin Biomedical Research Institute at VTC to utilize new microscopes that they may not have or when use of their own equipment is overtaxed. Startup companies across the region who may not have access to state-of-the-art equipment could also partner with VWCC to access the equipment.

“I really see it as a way to network and engage with community partners and local industries,” said Stacie Deaver, Program Head of Biotechnology Career Studies Certificate. “This could be an avenue to open opportunities for the science economy in the area.”

Entering the new Fab Lab on the first floor, you can immediately see the incorporation of real-world environment. The black-painted ceiling and cement floor offer an industrial design to the space. A garage door allows for additions of large equipment like a robot or over-sized machine for students to work on. It also extends the Lab to the outdoors with a patio offering students outdoor space and gives visibility to the activity to those passing by on Colonial Avenue.

Tapping into industries and understanding the current and future needs for employment and skills has been a long-term goal of the STEM program, and the new space reflects this commitment.

Wages and employment opportunities are known to be higher in STEM fields. According to the Pew Research Center, the average full-time STEM worker earns $54,575, or 26% more than a non-STEM worker.

“Through our community partnerships, we are able to offer access to an employable workforce both to existing industries and those looking to come to the area,” said White. “We see great opportunity to increase the visibility of the employability of our students through current and future partnerships.”

Leaders across the community agree that the new building and equipment will better prepare VWCC students and offer them greater employment opportunities.

“Harnessing innovation is essential to a forward-thinking institution — and that’s what Virginia Western makes possible,” said Neil D. Wilkin Jr., CEO of Optical Cable Corp. and Chair of the Virginia Western Community College Educational Foundation. “With the opening of its new STEM facility, the College is poised to meet our region’s business and community needs with invention, flexibility and an eye to what comes next.”

New equipment in the STEM Building includes:

- Phase Contrast Fluorescence Microscope: Detects the presence of materials, such as protein, and identifies the location of materials in relation to other structures in a cell or tissue.

- Multiphoton Confocal Microscope: Provides high-resolution fluorescent imaging of cellular processes or other materials and generates 3D images of structures using laser scanning to improve resolution.

- Scanning Electron Microscope: Provides visibility at 250 to 500 times the magnification of most light microscopes, with focused electron beams to show detailed features of samples and composition and topography information. This microscope allows visualization at the nanometer level.

- 4 new spectrometers: Used in analytical chemistry to determine information about an object or substance, these sophisticated instruments employ a variety of methods to identify and characterize materials and molecules.

- Collaborative Robot: Much like industrial robots that are common in manufacturing, the largest difference between the two is that collaborative robots are designed to safely work with human operators rather than in lieu of operators. The robot can easily be taught new processes and tasks as operators or operations change, without safety concerns.